The future of electric aviation just took a literal leap forward. BETA Technologies, the Vermont-based electric aircraft developer, has achieved a significant milestone with the first production test flight of its ALIA CX300 eCTOL aircraft, piloted by none other than BETA’s founder and CEO, Kyle Clark.

This achievement marks a pivotal step toward BETA’s goal of bringing a fully electric, conventional takeoff aircraft to market by 2025.

A Journey from Concept to Flight

BETA’s journey began three years ago with the debut of the ALIA–250, an eVTOL (electric vertical takeoff and landing) model that has since evolved into the ALIA VTOL. Now, BETA is pursuing a dual approach with the ALIA CX300, designed to offer both passenger and cargo transport options in a conventional runway-dependent aircraft.

With 200 cubic feet of cargo space and the ability to transport up to five passengers, this production-ready aircraft has already logged thousands of test miles as it moves toward full FAA Part 23 certification for commercial operations.

The First Flight of the ALIA CX300

Recently, BETA completed the production build of the ALIA CX300 in its 200,000-square-foot manufacturing facility in Burlington, Vermont. Following a rigorous FAA inspection, the CX300 received a Multipurpose Special Airworthiness Certificate allowing BETA to begin test flights.

Taking the controls himself, Clark took the CX300 on its maiden production flight, climbing to an altitude of 7,000 feet over nearly an hour to evaluate the aircraft’s stability, handling, and control points. This successful test showcased the CX300’s readiness for further testing and market demonstrations.

Clark expressed his excitement after the flight, calling it “a result of years of hard work” and an accomplishment that propels BETA into “an exciting new phase.” The CX300 isn’t just about flight—it’s about delivering an electric aircraft that is efficient, reliable, and designed to meet the demands of both passenger and cargo transport.

Building More Than an Aircraft

What sets this achievement apart is BETA’s commitment to building a full-scale, efficient production system. According to Clark, the first production build provided invaluable insights into manufacturing efficiency, labor demands, and quality control—data that BETA is already applying to improve its assembly lines.

The CX300 is designed to offer more than just electric propulsion; it’s an efficient, repeatable product that combines BETA’s innovative engineering with scalable production.

Key Specifications of the ALIA CX300

To highlight the CX300’s design, here are some of its most notable specifications:

- Wingspan: 50 feet

- Propulsion: One H500A electric motor with a 5-blade propeller

- Maximum Range: 336 nautical miles on a single charge

- Top Speed: 135 knots (about 155 mph)

- Charge Time: Less than one hour for a full recharge

This approach allows BETA to improve production efficiency for each CX300, ultimately aiming to meet rising demand from customers like Air New Zealand, Bristow Group, and United Therapeutics.

This interest highlights a growing market for electric aviation technology, offering practical solutions not just for passenger flights but also for short-haul cargo transport.

What’s Next for the ALIA CX300?

As BETA works to log the 50 hours of required flight testing, the CX300 will soon move into broader pilot training and market survey operations. This milestone will allow BETA to conduct public demonstrations, build customer interest, and expand testing beyond Vermont.

With each test, BETA gets closer to delivering the world’s first fleet of electric conventional takeoff aircraft. And while the ALIA VTOL remains in active development, the CX300 is positioned to lead BETA’s charge into the commercial market by 2025.

Charging Toward the Future of Flight

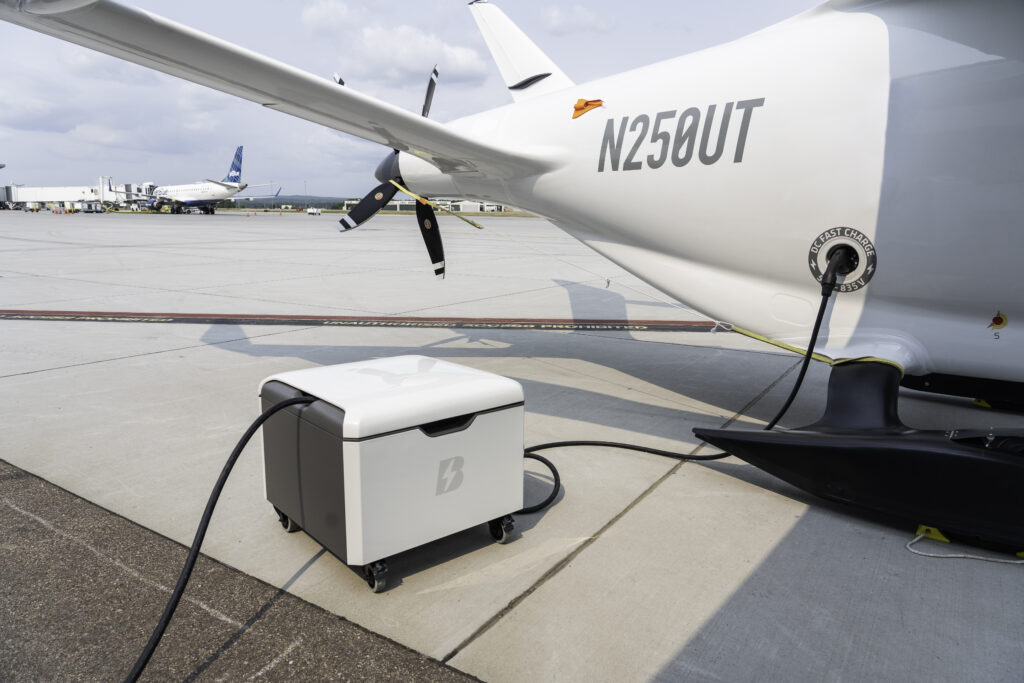

To support its fleet, BETA has been setting up a network of charging stations. With over 32 charging sites already operational and plans for more than 50 additional locations, BETA is creating the infrastructure to support not only electric aircraft but also ground-based EVs, ensuring a sustainable and versatile ecosystem for electric transportation.

Charge Complete

BETA’s production flight campaign is officially airborne, marking a pivotal moment in electric aviation. With the CX300’s successful flight, BETA is one step closer to electrifying the skies, proving that the future of air travel is indeed bright—and battery-powered.