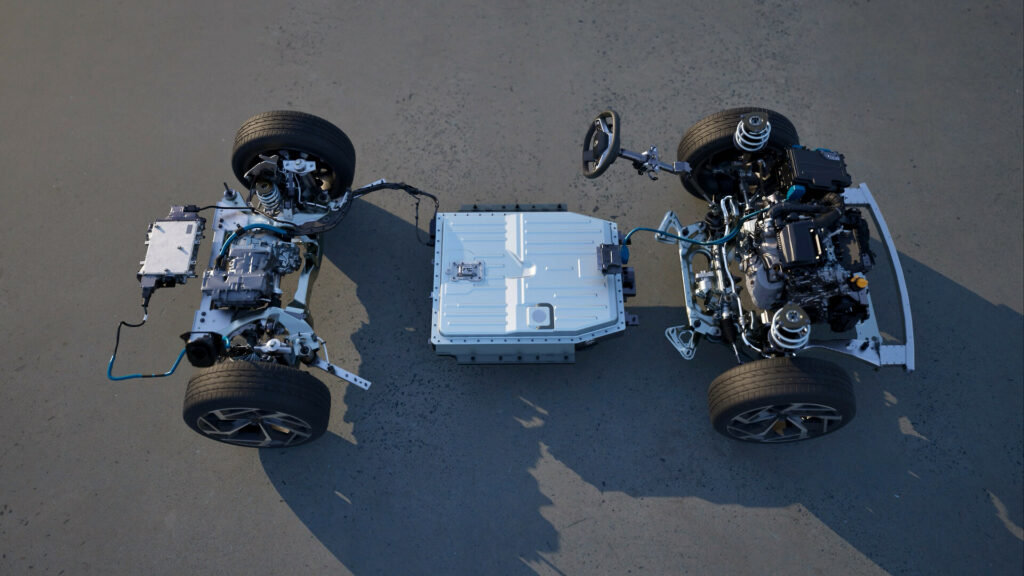

Ampere, the European leader in intelligent EV solutions, is making waves in the electric vehicle market with its ambitious new battery strategy. The company has announced plans to incorporate Lithium Iron Phosphate (LFP) technology alongside the current Nickel Cobalt Manganese (NCM) batteries used by Renault Group. This strategic decision is set to revolutionize their battery production process, ensuring cost-effectiveness and enhancing vehicle performance.

Ampere’s new battery plan is a direct response to the ever-changing market dynamics and technological advancements. By working closely with LG Energy Solution and CATL, Ampere aims to establish a robust and integrated value chain across Europe. This collaboration will ensure the competitiveness of LFP technology in their European-manufactured vehicles. Both LG Energy Solution and CATL will supply LFP batteries for various Renault and Alpine models, meeting battery requirements until 2030.

The same LG that’s probably responsible for powering your phone will work with Ampere to power your EV.

Cutting-Edge Innovations: Cell-to-Pack Technology

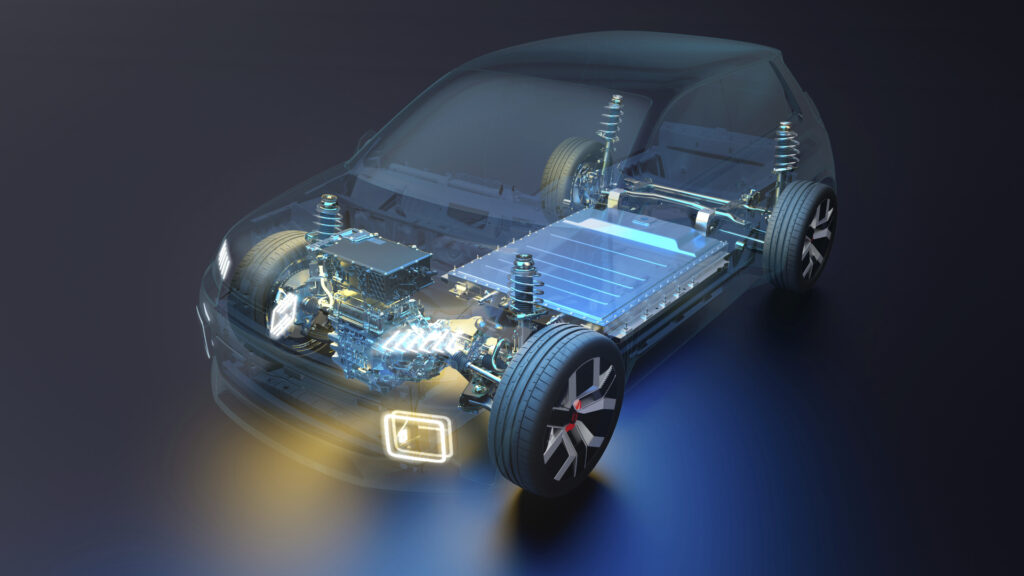

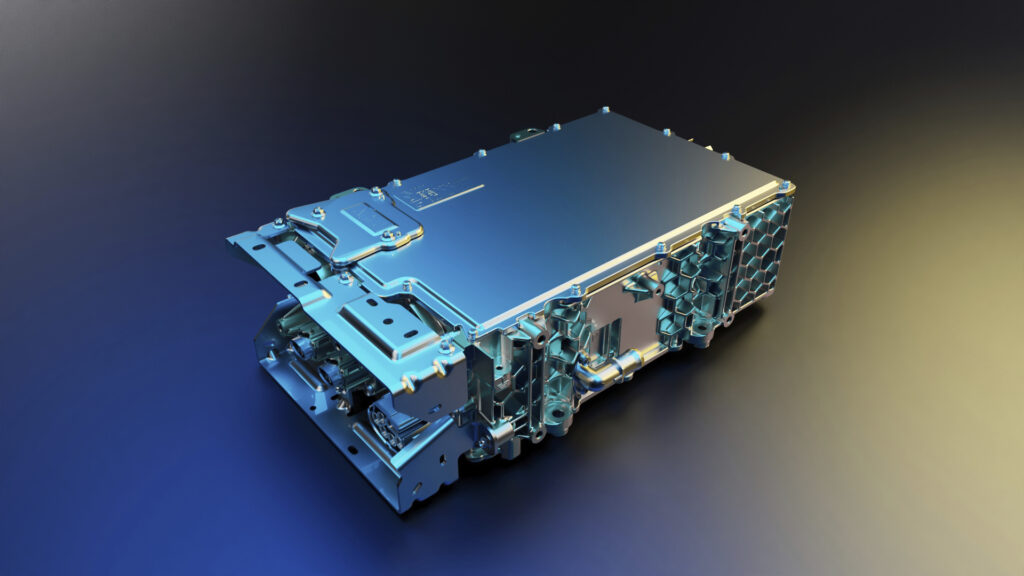

One of the most significant advancements in Ampere’s new battery strategy is the development of Cell-to-Pack technology in partnership with LG Energy Solution. This world-first innovation for pouch-type batteries allows more cells to be integrated into a given space, thereby increasing the onboard energy capacity and enhancing the vehicle’s range. Additionally, this technology is expected to reduce battery costs by around 20% starting in 2026. Affordable EVs are just what the automotive market needs, so we’re probably on the right track

Collaborations with Leading Battery Partners

Ampere is leveraging its relationships with four leading battery partners to accelerate its progress in a fast-evolving environment:

- AESC: Located within Ampere ElectriCity hub in Douai, France, specializing in NCM batteries.

- CATL: Providing LFP technology from the plant in Hungary.

- LGES: Supplying both NCM and LFP batteries from the plant in Poland.

- Verkor: Offering NCM technology from its gigafactory in Dunkerque, France.

These batteries are assembled at the Ampere ElectriCity facility in Douai, ensuring a streamlined and efficient production process.

The Rise of LFP Technology

LFP technology has seen significant advancements in recent years, making it a viable alternative to NCM batteries. LFP batteries are less energy-intensive and more cost-effective, making them ideal for small and midsize cars. This technology will be integrated into Ampere’s vehicles starting in early 2026, marking a significant milestone in the democratization of affordable electric vehicles in Europe.

Leadership Perspectives

“In a fast-changing and competitive environment, our battery strategy is proof of the efficiency of Ampere’s open and horizontal approach with best-in-class partners, ensuring smart capital allocation, flexibility, and rapid execution,” said Josep Maria Recasens, Chief Operating Officer of Ampere. This approach aligns with Ampere’s roadmap to reduce costs by 40% before launching the next generation of vehicles.

Philippe Brunet, SVP Powertrain and EV Engineering at Ampere, emphasized the importance of innovation in battery technology. “The work we’ve done with LG Energy Solution has enabled us to localize the entire value chain around LFP technology in Europe, and significantly increase its competitiveness, including with ‘Cell-to-Pack’. Innovation in batteries is ongoing, and we are working far upstream – in particular with our Innovation Battery Cell Laboratory to open in Lardy in 2025 – to engage our partners early on with us, on the major transformations to come.”

Future Prospects and Market Impact

Ampere’s integration of LFP technology is set to make a significant impact on the EV market. By reducing battery costs and improving vehicle range, Ampere is positioning itself at the forefront of the EV revolution. The company’s commitment to innovation and strategic partnerships ensures it remains competitive in an increasingly crowded market.

The collaboration with LG Energy Solution marks a significant step in this journey. LGES will supply 39 gigawatt hours of LFP batteries to power approximately 590,000 vehicles. These batteries, produced in Poland, will play a crucial role in Ampere’s strategy to produce more affordable and efficient electric vehicles.

Addressing Market Challenges and Enhancing Vehicle Performance

Ampere’s decision to incorporate LFP technology addresses several key market challenges. The volatility in the supply chain and the rising cost of raw materials have put pressure on automakers to find cost-effective solutions. LFP batteries, being less reliant on expensive materials like cobalt and nickel, offer a more stable and affordable alternative. This shift not only reduces production costs but also ensures a more sustainable supply chain.

The integration of Cell-to-Pack technology is a game-changer for Ampere. By optimizing the space within the battery pack, this technology allows for more energy storage without increasing the size or weight of the battery. This results in improved vehicle performance, with longer driving ranges and better energy efficiency. The first models equipped with this technology are expected to hit the market by early 2026, setting a new standard for EV performance.

Ampere’s focus on LFP technology also aligns with its commitment to sustainability. LFP batteries are known for their longer lifespan and better thermal stability, reducing the risk of overheating and extending the battery’s usable life. This means fewer battery replacements and less electronic waste, contributing to a more sustainable automotive industry. Ampere’s efforts to localize the entire value chain in Europe further enhance its sustainability credentials by reducing the carbon footprint associated with battery production and transportation.

Competitive Edge in the EV Market

As the competition in the EV market intensifies, Ampere’s innovative approach gives it a competitive edge. The ability to offer high-performance, cost-effective batteries positions Ampere as a leader in the industry. By partnering with top-tier suppliers like LG Energy Solution and CATL, Ampere ensures that its vehicles are equipped with the latest and most efficient battery technologies. This not only enhances the appeal of their vehicles but also boosts consumer confidence in the brand.

Future-Ready Infrastructure

Ampere’s collaboration with its partners goes beyond just battery technology. The company’s investment in infrastructure, such as the Innovation Battery Cell Laboratory in Lardy, is crucial for staying ahead of future technological advancements. This facility will focus on developing next-generation battery technologies and engaging with partners early in the development process. By fostering innovation and collaboration, Ampere is well-positioned to lead the way in the next phase of the electric vehicle revolution.

Final Words

Ampere’s ambitious battery plan is a testament to its commitment to innovation and excellence in the EV industry. By integrating LFP technology and developing groundbreaking Cell-to-Pack solutions, Ampere is setting new standards for efficiency and performance. This strategic move not only enhances the competitiveness of their vehicles but also paves the way for a more sustainable and accessible electric future. As Ampere continues to collaborate with industry leaders and innovate, the future of electric mobility looks brighter than ever.

With these advancements, Ampere is not just keeping pace with the rapid changes in the automotive industry but is also driving the change, ensuring a more efficient, sustainable, and exciting future for electric vehicles in Europe and beyond.

In theory, Ampere’s collaboration with leaders in the battery segment is