Electric vehicles are reshaping how we think about transportation, and Mercedes-Benz (MBG.DE) is now challenging a fundamental assumption: where the brakes belong. Traditionally, brakes are tucked behind the wheels, quietly doing their job.

Mercedes’ new In-Drive braking system moves the action inside the electric drive unit itself, promising a lifetime of maintenance-free operation while delivering a slew of other benefits. Let’s unpack what this means for the future of EVs—and whether we’re ready to rethink how we stop.

Why Move the Brakes?

For most EVs, regenerative braking does the heavy lifting, reclaiming energy that would otherwise be lost as heat and feeding it back into the battery. In fact, regenerative braking handles 98% of deceleration in modern EVs. So why bother with friction brakes at all? That final 2%—critical for emergency stops and low-speed braking—still requires traditional brakes. Yet these brakes, rarely used, come with their own set of issues.

Over time, rust and corrosion from inactivity can cause performance to degrade, while brake dust contributes significantly to particulate pollution. Noise and wear also compromise both the driving experience and the visual appeal of the vehicle.

Mercedes’ In-Drive system is designed to solve all of these issues by fundamentally rethinking how braking systems work. Instead of patching up existing designs, the automaker has completely reimagined the braking process for EVs, setting a new standard for efficiency, sustainability, and performance.

How It Works

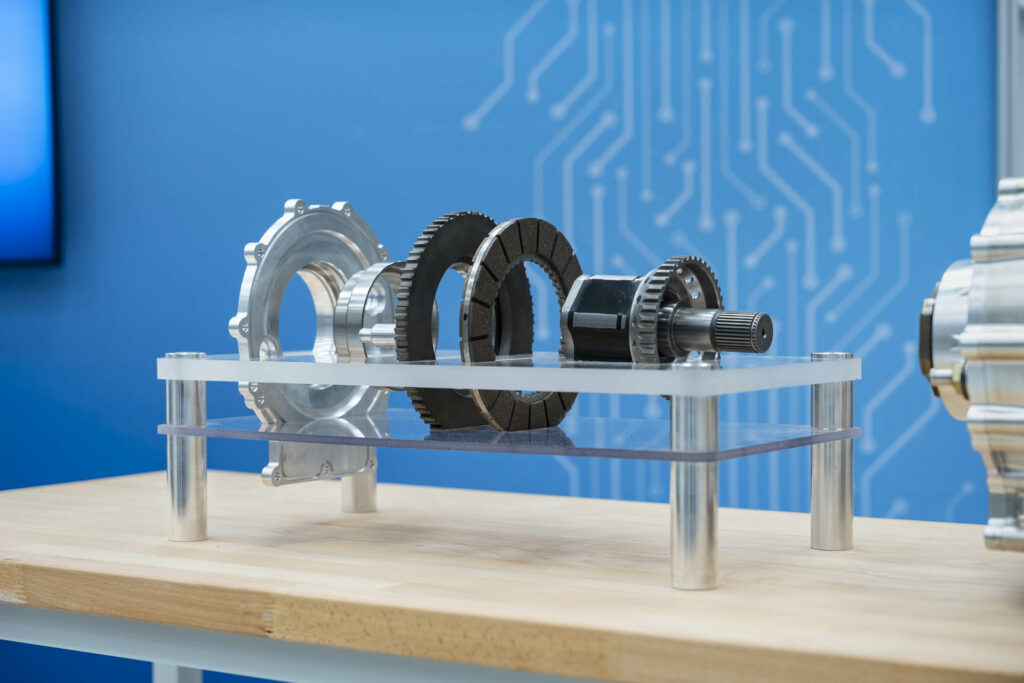

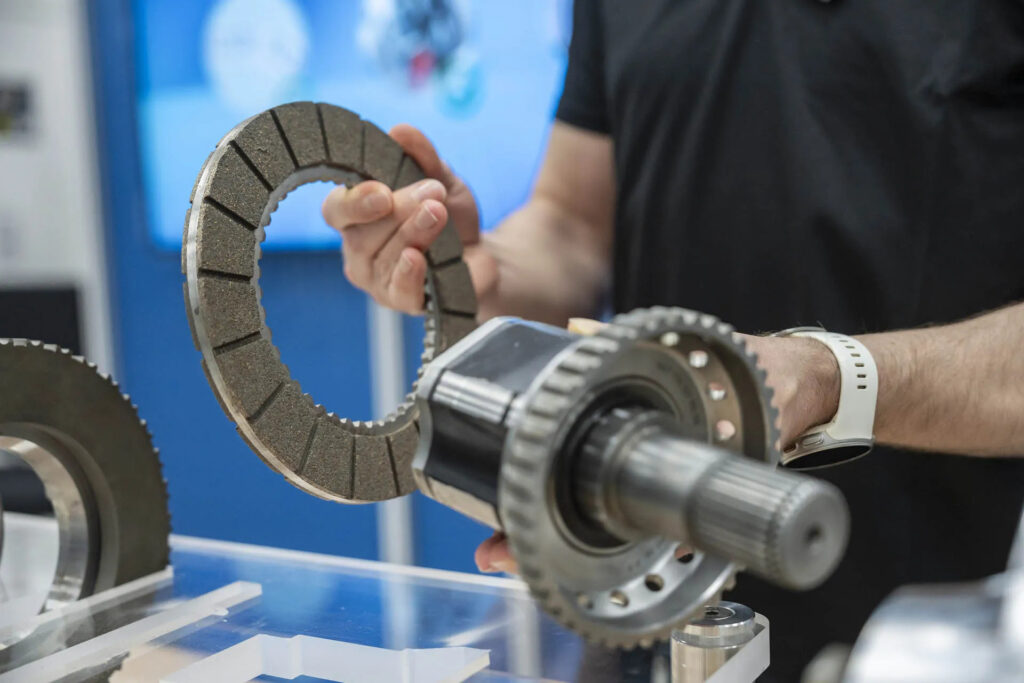

The In-Drive braking system breaks away from the traditional wheel-mounted disc and caliper setup. Instead, Mercedes has relocated the braking mechanism inside the drive unit at either end of the motor.

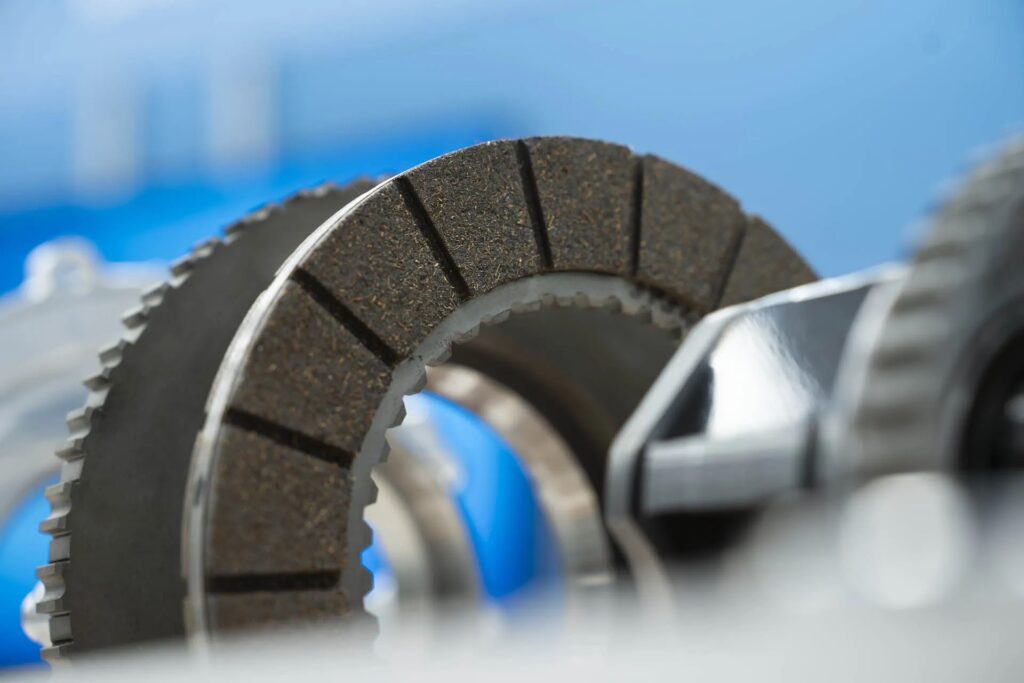

The system uses a stationary disc paired with a circular pad that spins with the motor. When braking is required, hydraulic pressure presses the pad against the stationary disc, effectively slowing the car.

The entire system is fully enclosed and water-cooled, eliminating the need for external airflow while preventing overheating during heavy use. Brake dust, a major environmental concern, is contained within a sealed sump, ensuring that no particulate emissions are released into the atmosphere.

This self-contained design not only eliminates mess but also makes the brakes maintenance-free for the vehicle’s lifetime, defined as 15 years or 186,400 miles.

By enclosing the brakes entirely, Mercedes has addressed several common problems in one innovative package. There’s no more rust forming on unused brakes, no more squeaky stops, and no need for periodic replacements.

The Advantages: Beyond the Basics

This innovation doesn’t just solve a single problem; it transforms several aspects of EV design and performance. By moving the braking system inboard, unsprung weight is significantly reduced. This shift improves handling and ride quality, making vehicles more agile and responsive.

Additionally, with no need to cool traditional brake discs, Mercedes designers have the freedom to create fully covered wheels. These aerodynamic designs reduce drag, boosting efficiency and extending the range of the vehicle.

Sustainability is also a key advantage. Brake dust is a growing concern as stricter emissions standards, such as Europe’s upcoming Euro 7 regulations, take effect. The In-Drive system’s enclosed design captures brake dust, ensuring that it doesn’t pollute the air. By addressing this often-overlooked source of emissions, Mercedes is pushing EVs toward a cleaner, more environmentally friendly future.

The system also brings practical benefits for drivers. Enclosed brakes eliminate the noise and wear that come with traditional systems, offering a quieter and more refined driving experience. While the initial costs of the system may be higher, Mercedes claims that the lack of maintenance and replacement parts will make the In-Drive system more cost-effective in the long run.

The Skeptic’s Corner: Is It Too Good to Be True?

Mercedes’ vision for the future of braking sounds revolutionary, but it raises questions that only time can answer. Cost remains a major hurdle. While the technology is currently more expensive than traditional setups, Mercedes is actively working to bring costs down. There’s also the challenge of market adoption.

Some enthusiasts may resist the idea of losing wheel-mounted brakes, which are often seen as essential for performance vehicles and visually iconic in their own right.

Reliability in real-world conditions is another unknown. While Mercedes projects a 15-year lifespan, vehicles often face unpredictable scenarios that could put these claims to the test. However, with active testing already underway, Mercedes seems confident that the system will perform as promised.

The company hasn’t confirmed when or which models will debut the technology, but all signs point to production readiness within a few years.

Charge Complete

Mercedes-Benz’s In-Drive braking system represents a bold leap forward in EV innovation. By relocating the brakes from the wheels to the drive unit, the automaker has addressed critical pain points like brake dust emissions, unsprung weight, and maintenance costs. This reimagining of braking systems opens the door to greater design flexibility, improved performance, and a cleaner environment.

If Mercedes delivers on its promises, the In-Drive system could set a new standard for braking in electric vehicles. While questions about cost and adoption remain, the potential benefits far outweigh the risks.

In a rapidly evolving automotive landscape, this innovation positions Mercedes as a leader in the race toward a smarter, more sustainable future. Could this be the braking revolution EVs have been waiting for? It’s starting to look like the answer is yes.

This sounds good to me, but I will probably die before I wear out my old cars.